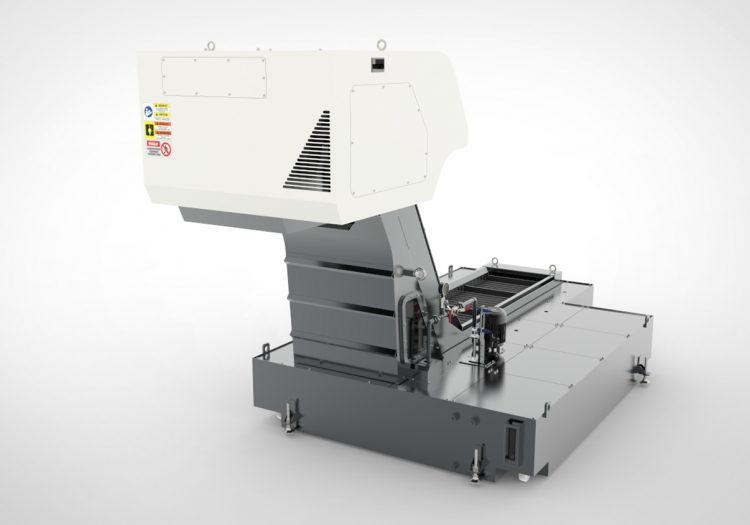

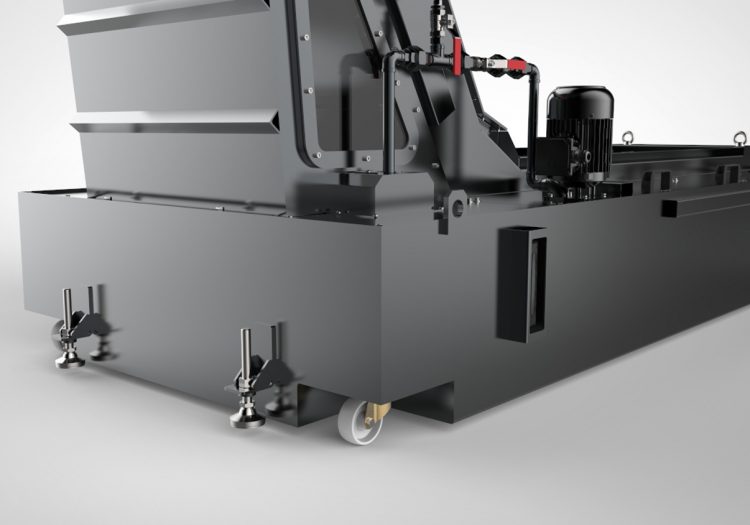

Drum filter unit ensures problem-free conveying dusty chips and crumb chips with its special designed drag conveyor system. Filtered drum filters coolant around 50 microns and makse it possible for reuse in the system. Coolant comes from amchining center is poured into dirty water reservoir of the drum filter and dusty and crumb chips are deposited to bottom in this reservoir and then transmitted to chips reservoir by scraping method. Thus, chips are seperated from liquid by scraping method.

Remaining liquid is cleaned up by passing through 50 micron metal filter in the drum system and transmitted to the clean water tank from the drum. Coolant is returned back to the system from this tank. It is also possible to add cooling unit to the clean-coolant tank if requested.

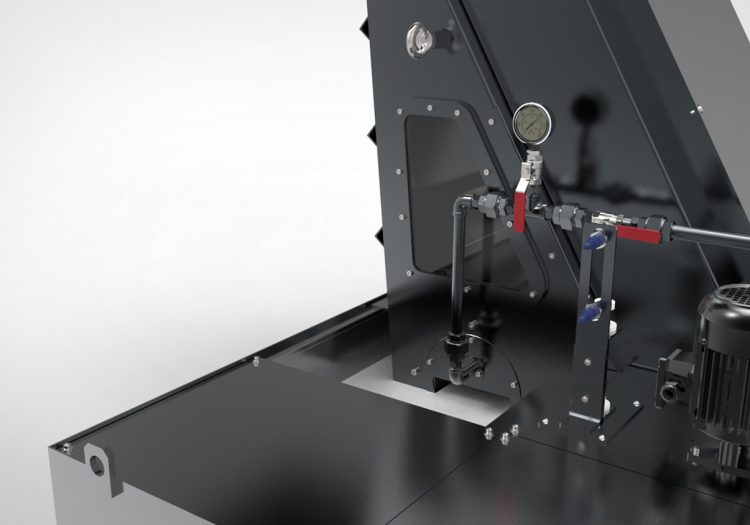

The metal filter is cleaned up periodically with pressure by internal washing system. This process is repeated continuously. The biggest advantage of the drum filter unit is there is no additional expense, such as paper filter, since the drum filter is made of metal. This filter is long lasting and doesn’t need to be replaced for a long time. In addition, it doesn’t generate any environmental pollution due to lack of use of a paper filter.