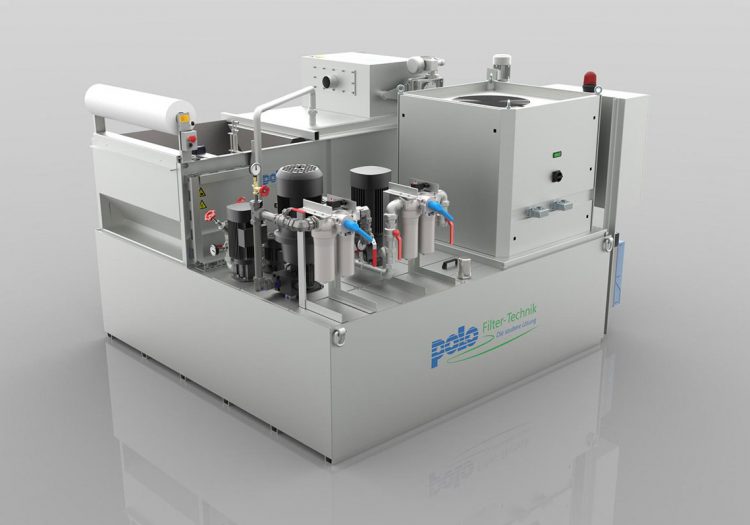

Central filtration systems enable the filtration and recycling of multiple processing center refrigerant liquids in a single place at the production plants that manufacture machining.

Advantages?

High capacity

The filtration machine can be produced in the desired capacity by calculating according to the total need. More than one pump can be used. In this way, liquid filtration is provided in large capacities.

Less space coverage

Since the individual systems are produced separately for each machining center, they serve only that machine. This leads to the loss of an area beside each machining center. In central filtration, however, all liquids are collected and filtered by means of a machine lifting unit. This gives you the chance to gain a very serious field of production.

Low cost

Manipulation of filtration from one location helps to reduce operation costs. The coolant is automatically added when it is deflated, cooling is still provided from a single center. Also, since the paper change is made from a single point, this expense is greatly reduced. In addition, because electricity consumption is still provided in one spot, very serious savings are made.

Easier management of the system

Central filtration makes management much easier as it collects the system into a single point. It is easy to care for the machine, change paper, make fat from a point of need.