Functional principle:

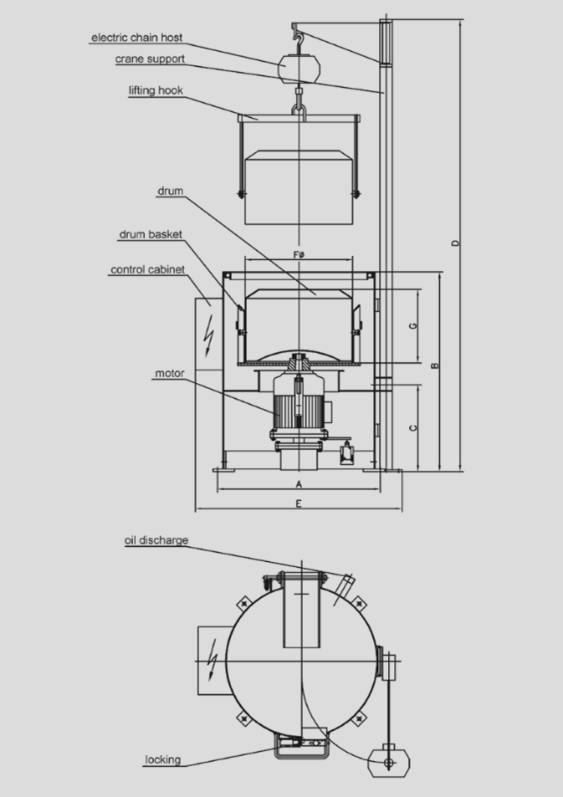

The basket can be elevated into the centrifuge using a lifting hook. When the drum is placed into the centrifuge an individually set centrifuging time begins to run. After completion of the centrifuging process, the drum is taken out and the process can be repeated with the next wet material.

Batch wringer are constructed for a long lasting continuous operation. The electro-magnetic lid locking, an unbalance detection switch and the standstill control provide maximum operational safety.

Optional accessories are available:

Rotation speed controller, crane support with pivot arm or an electric chain host, heating, tank, transport cart for the drum or customised carrier e.g. for boxes or workpieces. Even custom build models in stainless steel or EX protected are available on request.

Advantages:

- Turnkey delivery and easiest handling

- Perfect application for manual or half-automatic de-oiling or drying and conservation of turning workpieces, stampings and blanks

- Very long service life, operation free of vibrations

- Compact and easy to maintain, e. low maintenance costs and quick return of investment

- Dryness up to 1% residual moisture possible

- Standard execution consists of lid with pneumatic spring and electro-magnetic lid locking, unbalance detection switch and standstill control

- Including control cabinet laterally placed, e. not in swivel range of crane