Hot Parts Conveyor

Hot part transport conveyor is a heavy-duty type of transport system that allows metal billets or pre-forging parts that are treated with high temperatures (usually 900-1250oC) in induction furnaces to be transported to forging press, rolling mill or the next process station without losing their thermal properties and deformation.

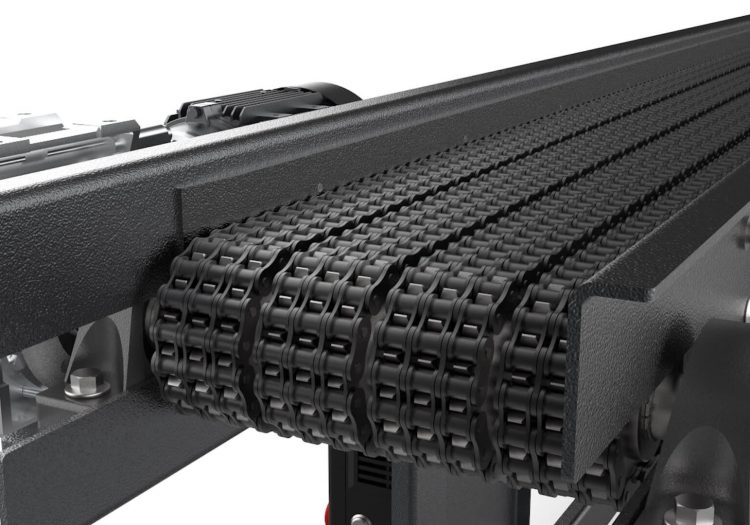

These types of conveyors are designed to be resistant against high temperatures and impact loads, and they are manufactured as chain, pallet or rotary table types suitable for the forging process.

This system both improves human safety in the production line and minimizes energy losses and non-process times by optimizing the hot part transfer.

Types and Shapes of Parts to be Transported

Metal parts used in the forging process are generally divided into the following categories:

- Cylindrical Billets/Blocks

- Dimensions: Diameter Ø20 mm – Ø300 mm, Length 50 mm – 1000 mm

- Weight: 1 kg – 150 kg

- Material: Carbon steels, alloy steels, stainless steels etc.

- Area of use: Shaft and axle production

- Flat sheets and plates

- Dimensions: 100 mm x 100 mm – 500 mm x 500 mm

- Weight: 5 kg – 200 kg

- Material: Low and high carbon steels and stainless steels

- Area of use: Machine parts, flanges

- Pre-formed parts (Near-Net-Shape)

- Dimensions: Ø50 mm – Ø500 mm

- Weight: 10 kg – 250 kg

- Material: High strength forged steels

- Area of use: Engine parts, gear boxes, flanges

- Ring rolled parts

- Dimensions: inner diameter 200 mm – 1500 mm, thickness 10 mm – 200 mm

- Weight: 5kg – 300 kg

- Material: High temperature resistant steels

- Area of use: Bearings, aerospace industry parts

Production Capacity and Transport Requirements

The transport capacity of conveyors should be determined according to the pace of the production line and the characteristics of the parts to be transported.

| Parameter | Sample Values |

| Piece Quantity | 100 – 500 pieces/hour |

| Maximum Load | 10.000 kg/hour |

| Conveyor Width | 600 mm – 1200 mm |

| Conveyor Speed | 0.1 – 1.0 m/s (adjustable frequency controlled) |

| Working Time | 24 hour / 3 shifts |

| Maximum Temperature | 1250 °C |

The conveyor system can be supported with side rails, chain holder mechanism or special pallet transport elements, by considering the temperature and shapes of the parts to be transported.

Parts Requiring Special Conveyor Design

- Curved or conical shaped forged parts: Side guards should be added against the risk of falling.

- Large diameter rings: Requires special sorting and guiding mechanisms.

- Thin and long parts: Carriers providing equal load distribution should be used to prevent bending.