Scraper conveyors are used to convey small chips and particles which come from grinding and honing various composite materials such as iron, cast-iron, brass-alloys, and sintered metals.

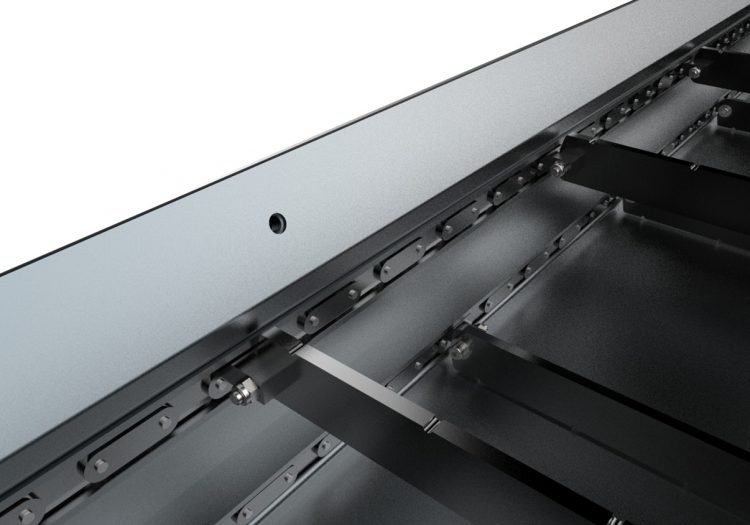

These models uses scraping method to take out the particles by rubbing them to the floor. The conveyor can also operate with no coolant (water) with friction safe hardox iron sheets mounted on the floor and in between the belt rails. Conveyer’s carriers are designed to separate cooling/cutting liquids from the particles and helps system to work smoother with no swaggering.

The belt pitch may vary based on amount of the particles and the size of the system. The motor and gear reduction unit has been selected to provide the best efficiency, while ensuring no or minimal cooling/cutting oil has being carried out with the particles.

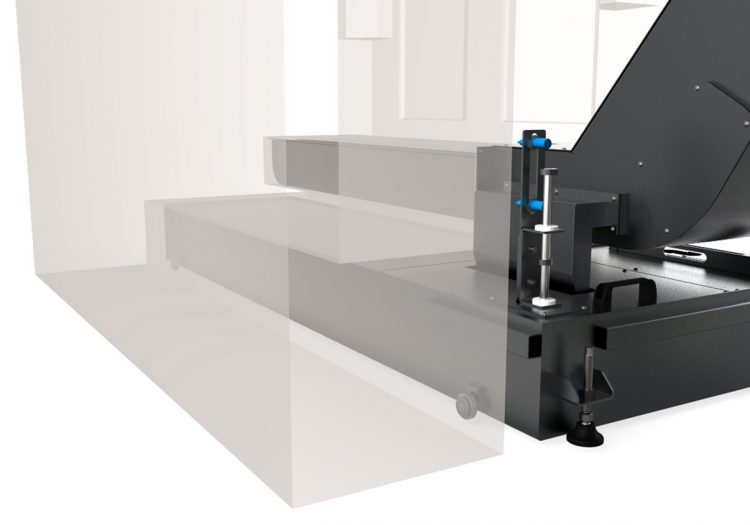

Conveyor can be controlled from the control unit on top of the body of the unit or can be mounted on the CNC bench with socket connection.

The conveyor can be manufactured in any angle or size (dimension). These conveyors can last long without complicated and frequent maintenance.