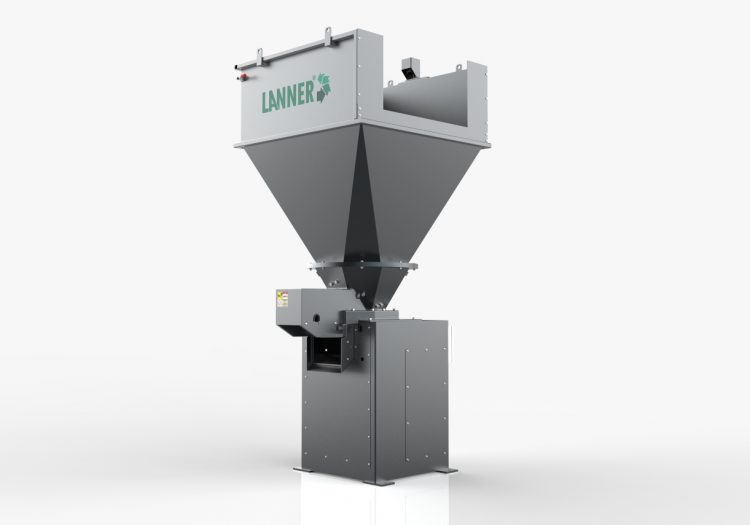

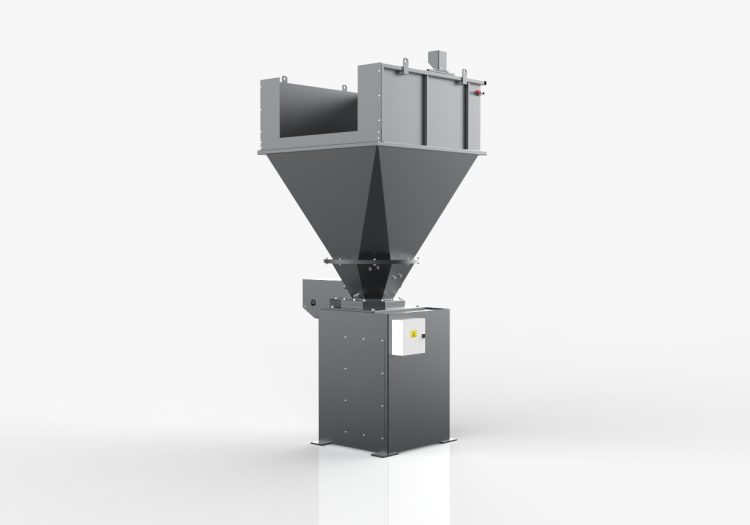

Functional principle:

The woolly and long chips with coolant content, which have to be crushed are fed with a conveyor or chip cart dumper into the infeed hopper of the chip crusher.

A rotating knife head with hardened crushing tools moves the complete chip ball against the hardened tearing blocks fixed on the crushing hopper. The precrushed chips fall downwards into the crushing mill, where they are crushed to a minimum size.

Mistakenly initated tramp metals such as bar ends and tools canbe ejected. Even tough chips can be crushed with this chip crusher. The chip crusher can be extended e.g. with an automatic diverter chute, with special material for life extension or with an electro-magnetic locked inspection cover on the infeed hopper.

Advantages:

- Vertical chip crusher

- Highly wear-resistant execution

- High-quality, hardened crushing tools

- Different grinding mills for various material

- Using in case of tough steel types possible

- Tramp metal ejector for mistakenly initiated tramp metals

- Compact and robust design

- Volume reduction of the chips up to 80%

- Smooth and fully automatic operation

- Easy to maintain due to quickly interchangeable wear parts

- Low energy requirement